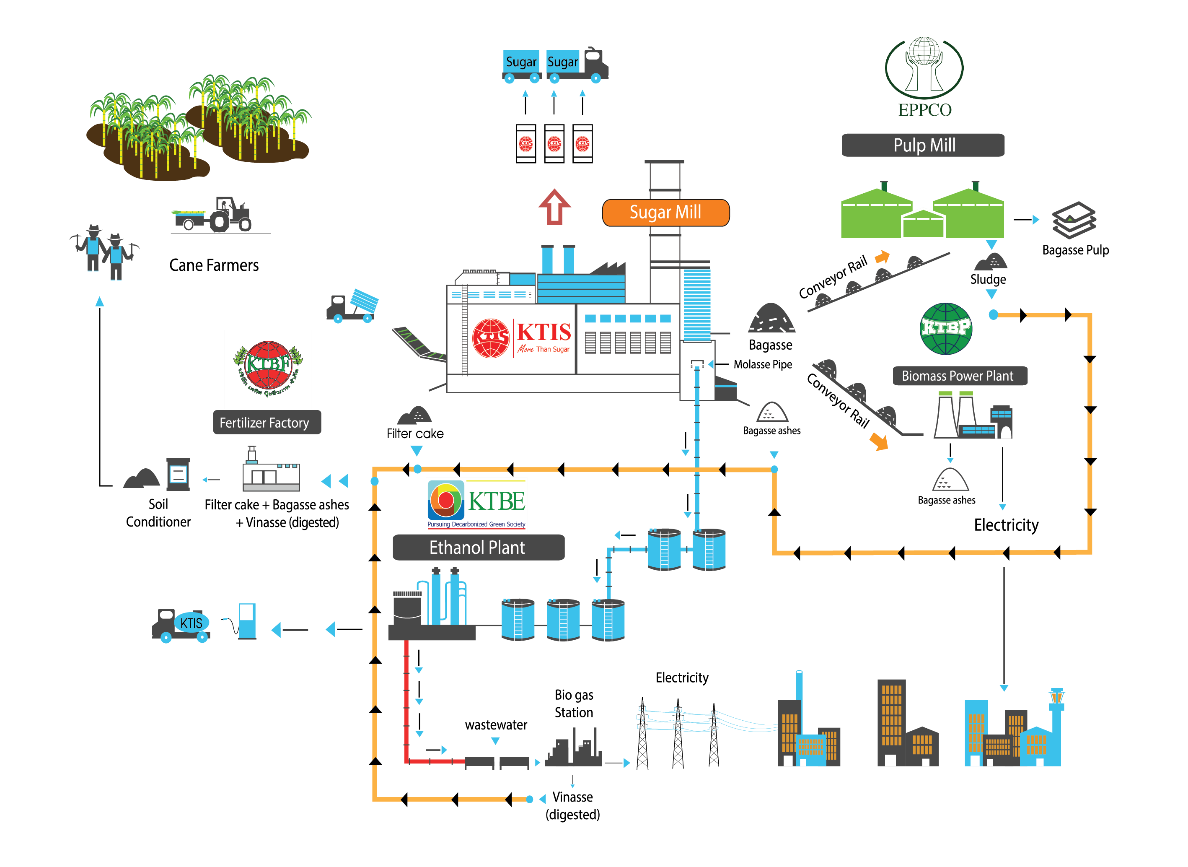

The manufacturing process of sugar from sugarcane is a process that yields various by-products. KTIS Group has invested in an integrated industrial business with the objective to be resourceful. For example, investing in a factory producing paper pulp from bagasse, ethanol from molasses, and a biomass power plant using bagasse from sugar mills as a raw material. In addition, the business has been designed to add value to various raw materials in the business networks without depending on external sources, which results in business stability and low risk in raw material shortage.

55,000

tons of sugarcane per day

At the KTIS Complex, where factories of KTIS Group are located, the manufacturing process has been designed as evolving the process from the core production of Kaset Thai factory to other related industrial factories, such as bagasse transportation with conveyor, or molasses transportation via pipeline, rather than transportation by trucks which requires a lot of fuel, in order to reduce the cost of transporting raw materials as well as conserve energy.

KTIS Complex is also ready to support the expansion of other related industrial factories, which will use by-products from the manufacturing process as raw materials, in order to enhance further products in the future.