Although KTIS Group operates on industrial business, it believes that a sustainable business must be a business that is eco-friendly. Hence, its principle of manufacturing processes is based on an eco- and energy-oriented belief.

Eco-friendly Manufacturing Processes

KTIS Group focuses on eco-friendly manufacturing processes; starting from the upstream for planting the sugarcane, in which KTIS Group has educated farmers to apply organic agriculture in their farming. For example, by using Trichogrammas to control insect pests of sugarcane, farmers can avoid using chemical substances in sugarcane farms, which is an agricultural method that does not disturb the natural ecology. KTIS Group has waste treatment systems, such as the recovery boiler system in a paper pulp factory and the biogas producing system in an ethanol factory, in order to treat the sewage before using it as fuel in the recycle-energy generation.

Additionally, KTIS Group has the concept of maximizing the benefits of by-products from manufacturing processes so there is little waste. Various kinds of organic waste from the processes will be brought to sugarcane farmers to be used for improving soil quality, such as dregs from filters in sugar production, sludge in paper pulp production, vinasse from ethanol production, and ashes from furnaces in electricity generation. Such organic materials can improve soil quality so the farmers can get good-quality sugarcane.

Safety for Consumers

KTIS Group strives on manufacturing food products and is committed to produce goods with standard quality and safety for consumption.

Sugar products of KTIS Group are made from high-quality sugarcane, which apply methods of organic agriculture in the cultivation and avoid using chemicals in sugarcane farms in order to obtain clean raw materials with no chemical impurities passing through the standard manufacturing process yielding clean sugar, which is safe for consumption.

Paper pulp products from Environment Pulp and Paper Co., Ltd. of KTIS Group are made from raw materials as 100% bagasse with no tree pulp.In addition, it does not use chlorine, which has high carcinogens, in the bleaching process so the pulp is suitable for food products and food containers. Due to such consideration and determination, paper pulp of Environment Pulp and Paper Co., Ltd. has currently become the first pulp products in Thailand to be certified with Good Manufacturing Practice (GMP) and Hazard Analysis and Critical Control Point (HACCP).

Paper Pulp Products from Bagasse

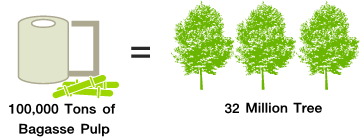

Each year, millions of trees have been cut down to be used as raw materials for paper pulp production, which will be transformed into dispensable products, such as tissue paper, printing paper, etc. Paper pulp of KTIS Group is different from regular pulp because it is made from bagasse as a by-product from the sugar manufacturing process. During each year, KTIS Group produces paper pulp from bagasse of 100,000 tons, which can replace tree cutting of 32 million trees.

Alternative Energy

Currently, the increasing world population requires higher energy consumption. While most kinds of energy are dispensable and cause pollution to the environment, KTIS Group emphasizes on utilizing energy for maximum benefits, starting from the manufacturing process that saves energy to generate alternative energy that is eco-friendly.

KTIS Group produces ethanol, which can be mixed in automobile fuel as the alternative energy to replace gasoline from foreign countries while saving money for the country. Additionally, ethanol still has higher combustion coefficient than gasoline so it yields complete combustion in the chamber and makes cleaner air in comparison with gasoline, which originates from fossils that causes a green-house effect.

Additionally, KTIS Group uses bagasse obtained from sugar production as fuel to generate steam and electricity in order to be used in the sugar manufacturing process and other related industries in the group. In addition, it sells the remaining electricity to the Provincial Electricity Authority (PEA) for distribution to the community. Currently, KTIS Group generates electricity to the PEA through generating units of 3 sugar factories and 1 biomass power plant, which has the capacity of 60 Mega Watts. Such electrical energy generated from bagasse is considered clean energy from biomass raw materials, which reduce carbon-dioxide release to the atmosphere significantly.

KTIS Group is extremely proud to be part of Thailand's generators of alternative energy produced endlessly from planted raw materials. This helps save money for the country as well as the world environment.